Headstock Repair: the rest of the story

Now the glue has dried, we can continue the

work. First thing we do is mark for new tuner holes. Start

by laying a straight edge along the edges of the existing

holes and drawing alignment lines. Next thing to do is space

and mark where the new holes will be within the alignment

lines. To do this I normally use a vernier caliper, but since

this lesson is how to do the work with very basic tools, I

used a crescent wrench. First set the jaws to distance between

the same edge of two of the existing holes. Place one edge

alont the inside edge of the last existing hole and draw a

line between the alignment lines. Place the same edge of the

wrench along the other side of the same tuner hole and draw

a second line.

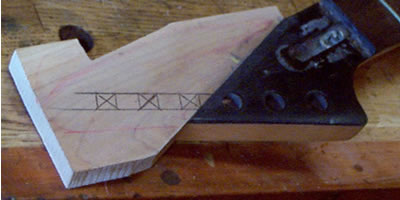

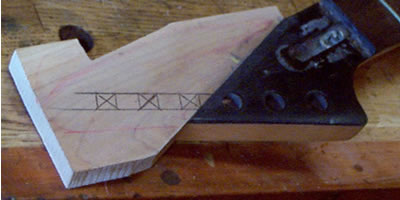

This picture shows marking the lines (the second

line is already done)

Now use the lines drawn as if they were the

last existing hole. You will wind up with the new holes marked

as small squares. Draw an X connecting the corners of each

square to locate the center. It will look like this.

Next, use a nail or something similar to center

punch each hole location at the center of the X. Use the existing

holes to determine the correct bit size (in this case 7/16)

and drill the new holes. Have a piece of scrap wood under

the headstock to prevent the back from splitting out. Also,

make certain to drill and mark from the face. The large body

of the tuners will hide any minor chipout which might occur.

(a drill press must be used. a cheap press that converts a

hand drill into a press is probably adequate) Now we draw

our new outline, using the holes as a guide.

picture showing holes drilled and outline sketched.

Now using a coping saw (I also used a straight

saw for the straight cut) cut the profile out as close to

the line as you are comfortable with.

here it is cut out

here it is cut out

Now use a rasp to remove the areas which need

heavy shaping, be sure to stay short of the final desired

level as there will be alot of sanding to remove the rasp

marks.

profiling w/ rasp

profiling w/ rasp

Next, using a sanding block and a pipe or something

similar, we sand to smooth everything out starting w/ 60grit

and working up to 320grit.

And we wind up with this.

It is ready for finish!

I'm not going to finish this one, remember

it is just for a junk guitar to test my pickups in.

Doing this repair "the hard way"

took about 2 hrs not including dry time. Normally this job

would have required less than 1hr. (I prefer to book joints

w/ a plane regardless)

|

here it is cut out

here it is cut out profiling w/ rasp

profiling w/ rasp